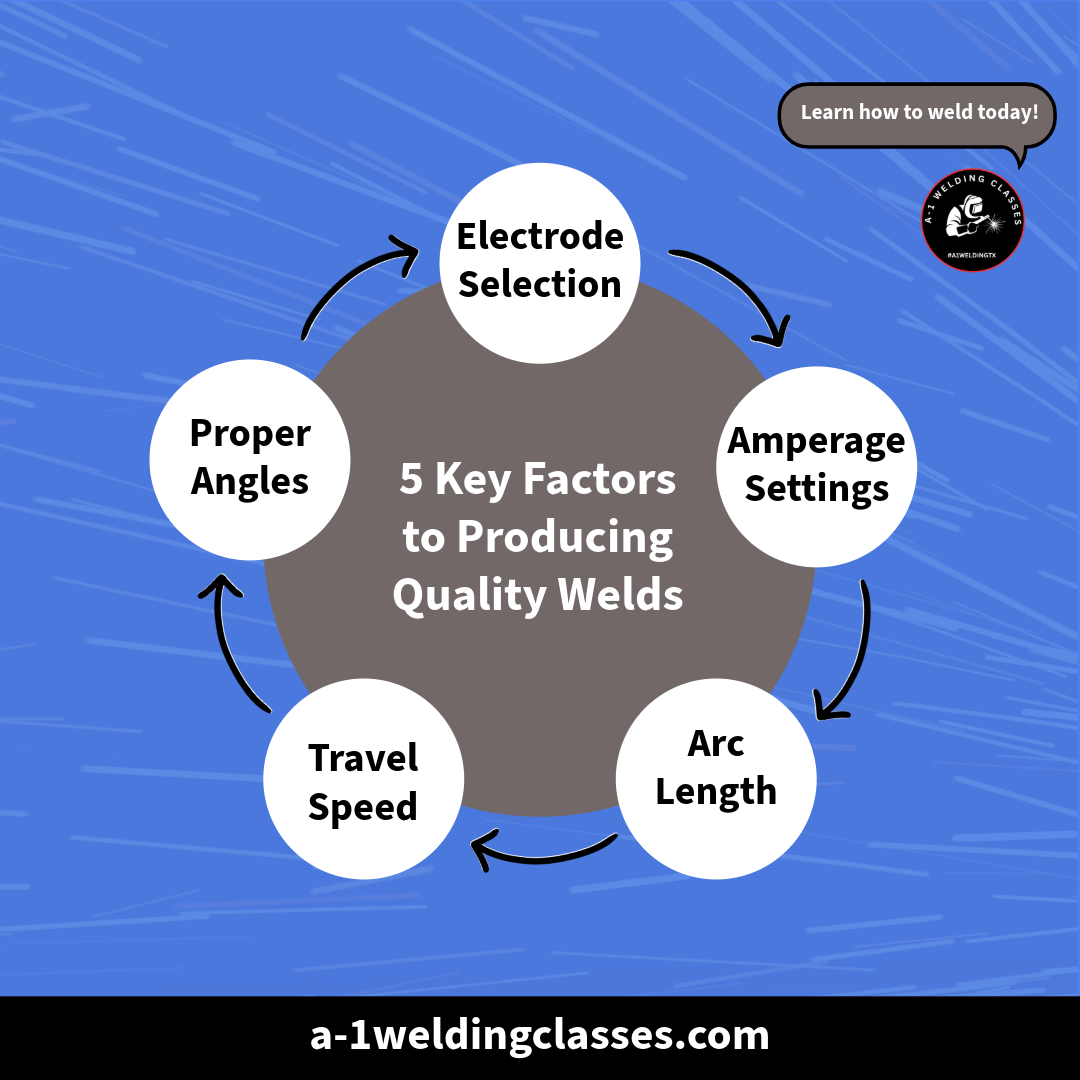

5 Key Factors to Producing Quality Welds

Today, we want to talk about the 5 key factors to producing quality welds. Welding is a skill that truly develops with repetition, but it’s not just about doing it, it’s about watching what you’re doing, paying attention to the puddle, the arc, the sound, and your resulting bead. Each of these key factors play a vital role and by focusing on them, you’ll build not just strong welds, but also a deep understanding of the craft. Mastering these 5 key factors is your roadmap to becoming a skilled welder and we can help get you through your journey.

Five key factors to producing quality welds.

1. Electrode Selection

First key factor is selecting the right electrode for the welding procedure based on thickness of material, joint type, and welding position.

2. Amperage Settings

Next being the amperage settings of your welding machine and knowing how these settings can influence your arc, penetration, and bead appearance.

3. Arc Length

The third key factor is your arc length, making sure you keep the correct distance between the electrode and workpiece ensuring you have the correct heat transfer and a properly shaped weld bead.

4. Travel Speed

The Fourth key factor is your travel speed, traveling too fast there is a chance you won’t get enough penetration or traveling too slow there is a chance you risk burning through your workpiece. Finding that steady, consistent travel speed allows the puddle to form correctly and the filler material to integrate seamlessly.

5. Proper Angles

Finally and perhaps the most important is proper angle, The angle at which you hold your torch or electrode directly impacts the heat distribution and the way the molten metal flows. A consistent, correct angle ensures you’re directing heat where you need it, creating a smooth, even bead and preventing defects

Teaching a Trade That Never fades