The Benefits of a Welding Career

One of the most rewarding benefits of learning to weld is the sense of accomplishment that comes with creating something tangible!! Imagine taking raw materials and transforming them into a beautiful piece of art or a functional item. It’s a skill…

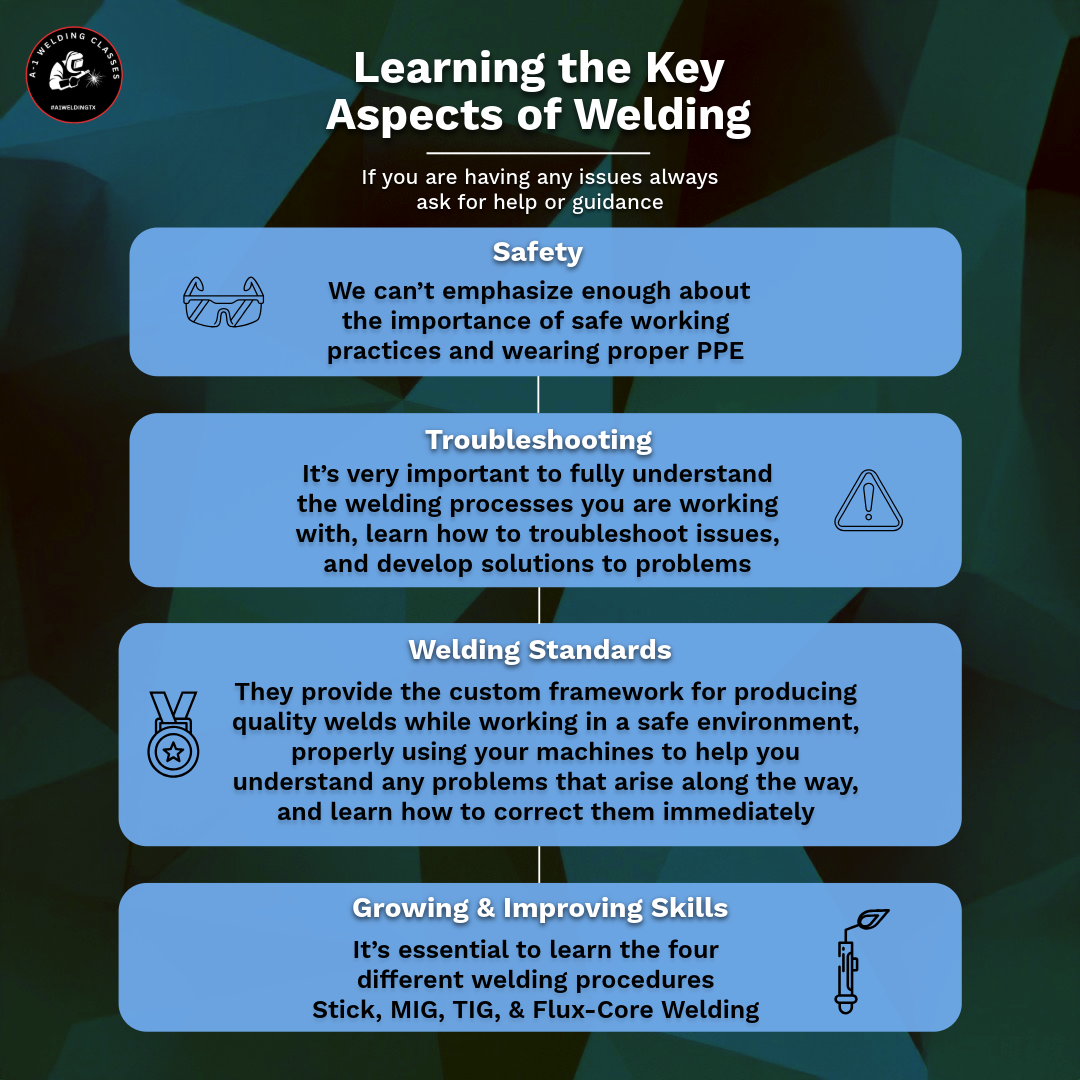

Learning The Key Aspects of Welding

One of the most rewarding aspects of learning to weld is the sense of accomplishment that comes with creating something tangible!! Imagine taking raw materials and transforming them into a beautiful piece of art or a functional item. It’s a skill that not only enhances your creativity but also boosts your confidence as you see your ideas come to life. Welding is more than just joining metal…

A-1 Welding Classes: What Kind of Welding Instructor Do You Want?

What kind of Welding Instructor do You want? Whether you’re just starting out or looking to refine your skills, the right instructor can make all the difference in your welding journey….

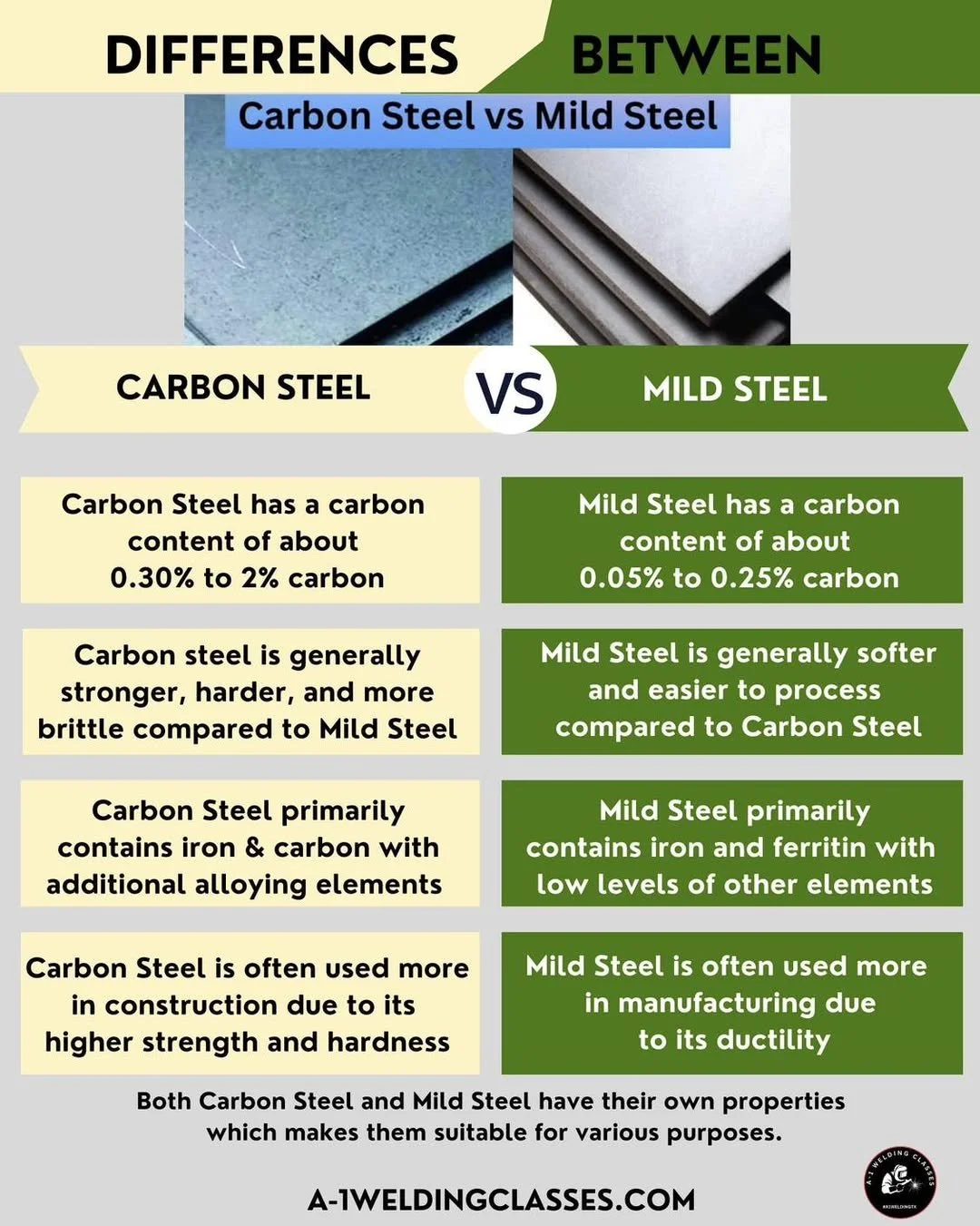

A-1 Welding Classes: Carbon Steel vs Mild Steel

You might be wondering, aren't they basically the same thing? Well, not quite! While they share a lot of similarities, the key difference lies in their carbon content. Let's take a look at what that means….

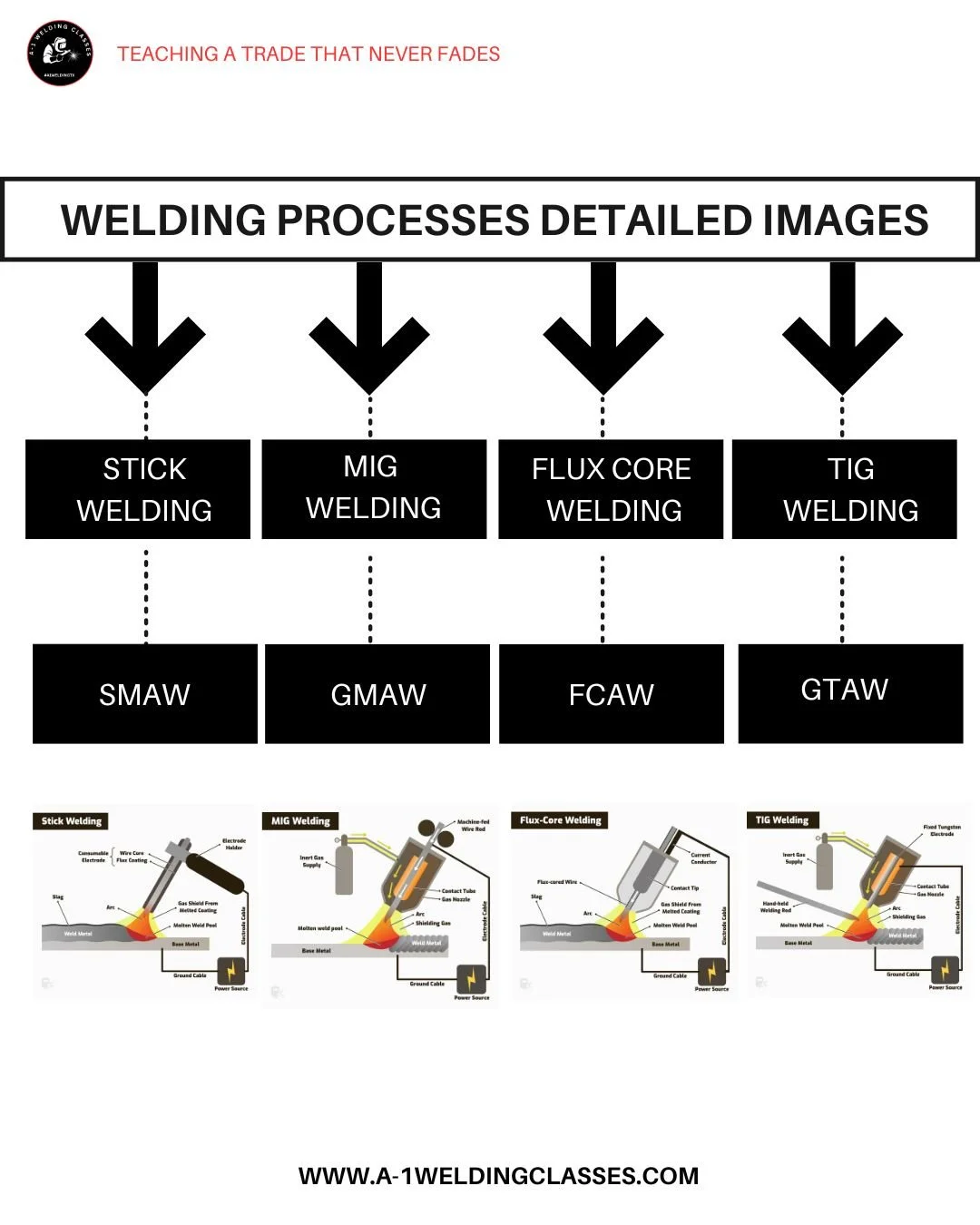

A-1 Welding Classes: Welding Processes Explained

Welding requires attention to detail. It’s a true craft, where every single movement, every adjustment, matters. It’s a skill honed through dedication and a deep understanding of each welding process…

4 Common Welding Processes that Bring Incredible Strength and Durability to our Infrastructure

Today we’re talking about the four common welding processes that bring incredible strength and durability to our infrastructure. First up, we have Stick Welding….

A-1 Welding Classes: Welding Abbreviations

Today, we’re talking about welding abbreviations, and trust us, once you understand these your confidence will soar even more! Think of these abbreviations as the shorthand that makes communication in the welding world incredibly efficient…

GMAW Diagram: The Components of a MIG Welding Gun

Knowing and understanding the components of a MIG welding gun is beneficial for several reasons, it helps you to recognize and resolve issues quickly, like poor wire feeding or inconsistent welds…

Flux-Core (FCAW) vs MIG Welding (GMAW): Choosing the Right Method

Have you ever wondered what welding process to use for your project? Today we are going over the differences between flux-core (FCAW) and MIG welding (GMAW), sure to help you make the best decision when it comes to choosing the right welding process for your project.

Unlocking Welding Success with Electrical Knowledge: The Vital Link Between Welding & Electricity

It’s a topic that’s absolutely fundamental to welding, yet sometimes overlooked, the vital link between welding and electricity! Think about it…every arc, every bead, every perfectly fused joint is a testament to your mastery of electrical principles.

Mastering Welding: Tips for Stick Welding (SMAW)

We created these stick welding tips to help remind you what to do during the welding process….

Mastering MIG Welding: Tips for Beginners

MIG welding is incredibly versatile, whether you’re working with thin sheet metal or thicker plates, it can handle them all, offering a clean and efficient way to create strong, lasting bonds….

Welding Tips: The Method for Welding Thick & Thin Materials, Joining the Two Materials

Have you ever found yourself staring at a welding project, wondering how to seamlessly join materials of vastly different thicknesses? Practice is key to finding the right settings and technique. Let’s take a look at some tips that might help you!

What Every Person Should Know Before Starting Their Welding Career

Embarking on a welding career is an exciting journey, and there are a few key things that will set you up for success from day one. So, as you continue exploring the world of welding, continue to practice, experiment, and enjoy the incredible journey of becoming a skilled welder.

5 Key Factors to Producing Quality Welds

Welding is a skill that truly develops with repetition, but it’s not just about doing it, it’s about watching what you’re doing, paying attention to the puddle, the arc, the sound, and your resulting bead. Each of these key factors play a vital role and by focusing on them, you’ll build not just strong welds, but also a deep understanding of the craft. Mastering these 5 key factors is your roadmap to becoming a skilled welder and we can help get you through your journey.

What is A Metal Fabricator? Understanding the Process of Metal Fabrication

Think of metal fabricators as the skilled artisans and engineers who transform raw metal into functional, beautiful, and essential components. It’s a process that involves a whole lot of precision, creativity, and a deep understanding of materials. At its core, metal fabrication is….

The Four Welding Processes That Every Welder Should Know: The Guide to Stick, Flux-Core, MIG & TIG Welding

Understanding and practicing these four welding processes, stick welding (SMAW), MIG welding (GMAW), flux-core welding (FCAW), and TIG welding (GTAW) will equip you with a robust skill set. They all use a power source with a welding lead and ground clamp, but what sets them apart, they are different types of arc welding, each using a different method for creating an arc to melt and fuse metal. Each has its own unique strengths. Knowing when and how to apply them is key to becoming a well rounded and capable skilled welder.

Is Welding Right for you? The Pros and Cons of Welding

Today, we want to talk about the pros and cons of welding which are both important considerations that come when pursuing this skilled trade.

Growth Through Welding: Personal, Economic, & Career Achievement

Welders play an essential role in America, many industries rely on a welders skills to build, maintain, and repair infrastructure, vehicles, buildings, manufactured products, and much more.

Personalized Training: The Importance of Personalized Welding Training

Do you want to learn how to weld? Our classes are 5:1 student to teacher ratio, this helps us provide personalized training to tailor to each students needs, which allows students to master their skills at their own pace and apply what they are learning to set realistic goals with their career. Students will learn 100% hands-on welding training from an instructor who has over 30 years of knowledge in the welding industry.