4 Common Welding Processes that Bring Incredible Strength and Durability to our Infrastructure

Today we’re talking about the four common welding processes that bring incredible strength and durability to our infrastructure!!

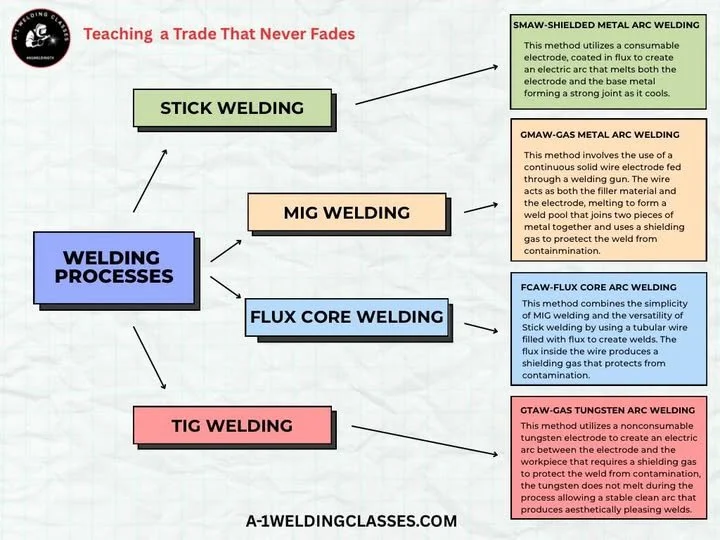

First up, we have Stick Welding aka Shielded Metal Arc Welding (SMAW). This is a classic for a reason. It uses a consumable electrode coated in flux, which melts to create the weld pool and also produces a shielding gas to protect it from the air. It's incredibly versatile, working well outdoors and on various metal types, making it a go-to for construction and repair.

Next, we have MIG Welding aka Gas Metal Arc Welding (GMAW). This is a popular choice for its speed and ease of use. Here, a continuous wire electrode is fed through a welding gun, and a shielding gas is supplied separately to protect the weld. MIG is fantastic for thinner materials and offers a cleaner finish, making it a favorite for automotive work and fabrication shops.

Then there’s Flux Core Welding aka Flux-Cored Arc Welding (FCAW). This process is similar to MIG, but the electrode wire is hollow and filled with flux. This flux provides shielding and can also add alloying elements to the weld. It's a robust option, particularly effective for welding thicker materials and in windy conditions, often seen in heavy industrial fabrication and structural steel work.

Finally, we have TIG Welding aka Gas Tungsten Arc Welding (GTAW). This process uses a non-consumable tungsten electrode to create the arc, and a separate filler rod is often used to add material. The shielding gas is also supplied separately. TIG is renowned for its precision and the beautiful, high-quality welds it produces, making it ideal for critical applications like aerospace and intricate artistic metalwork.

Each of these processes offers unique advantages and understanding them helps us appreciate the skill and science behind the metal structures that shape our world.

These four common welding processes are definitely worth exploring and knowing, especially if you want to get started in a Welding Career.

Teaching a Trade That Never Fades