A-1 Welding Classes: Welding Abbreviations

Today, we’re talking about welding abbreviations, and trust us, once you understand these your confidence will soar even more! Think of these abbreviations as the shorthand that makes communication in the welding world incredibly efficient. They save time, reduce confusion, and make sure everyone is on the same page. Understanding these abbreviations is like unlocking a new level of comprehension when you’re reading project plans or discussing techniques. It’s not about memorizing a massive list, but rather recognizing the most frequent ones that will appear in your work. The beauty of learning these abbreviations is that it empowers you. Helping you engage more deeply in conversations, understanding instructions more clearly, and even contribute more effectively to projects.

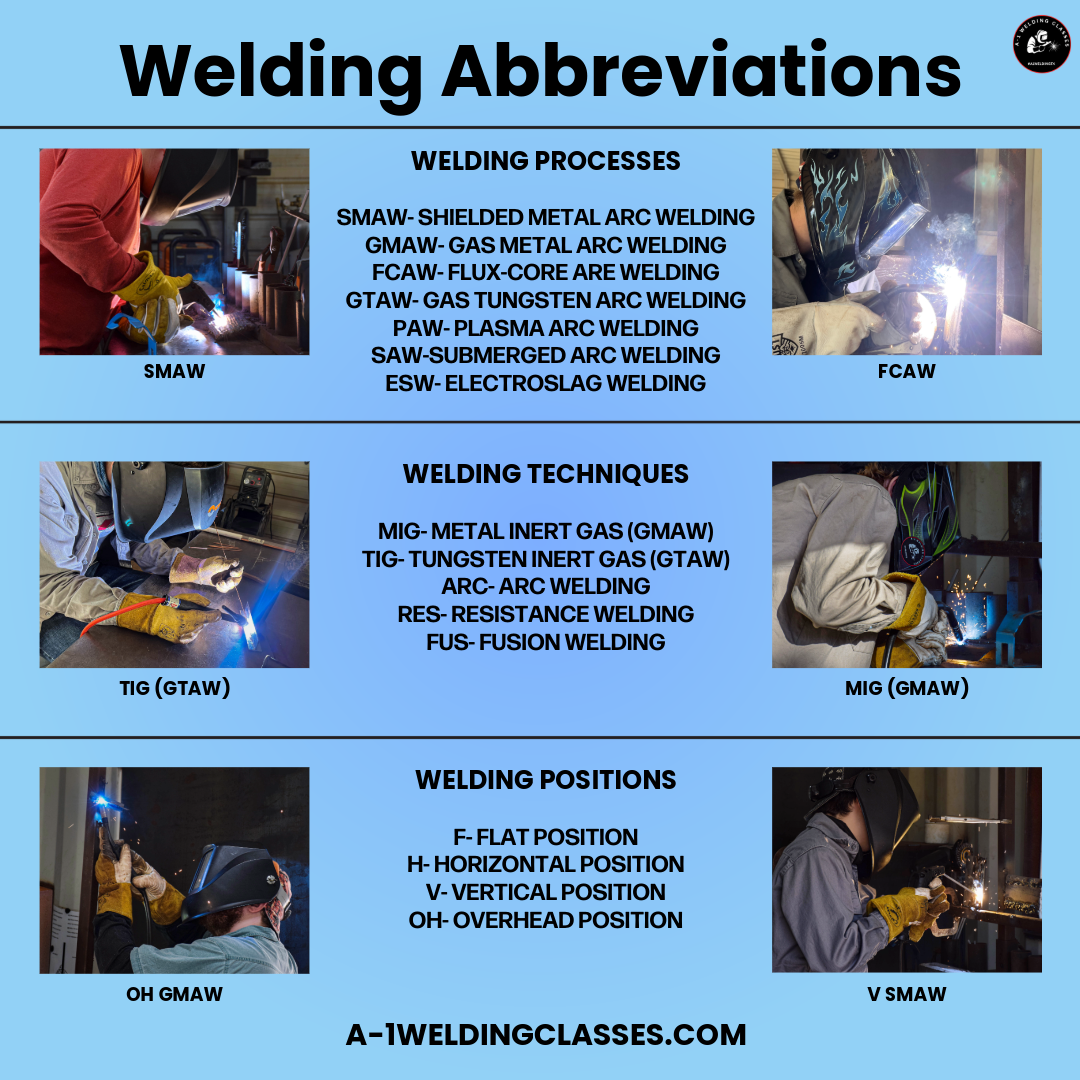

WELDING PROCESSES

SMAW-SHIELDED METAL ARC WELDING

GMAW- GAS METAL ARC WELDING

FCAW- FLUX-CORE ARC WELDING

GTAW- GAS TUNGSTEN ARC WELDING

PAW-PLASMA ARC WELDING

SAW-SUBMERGED ARC WELDING

ESW- ELECTROSLAG WELDING

WELDING TECHNIQUES

MIG- METAL INERT GAS (GMAW)

TIG- TUNGSTEN INERT GAS (GTAW)

ARC- ARC WELDING

RES- RESISTANCE WELDING

FUS- FUSION WELDING

WELDING POSITIONS

F-FLAT POSITION

H-HORIZONTAL POSITION

V- VERTICAL POSITION

OH- OVERHEAD POSITION

Teaching a Trade That Never Fades